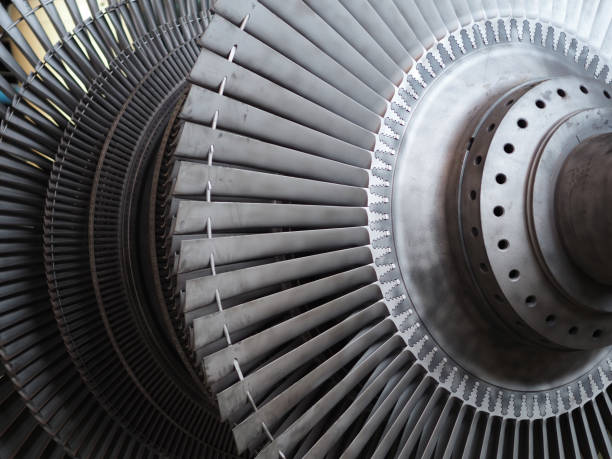

What Is a Steam Turbine Diaphragm? Understanding Its Function, Design & Role in Efficiency

Steam turbines are critical components in power generation, industrial processing, and mechanical drive applications. They convert thermal energy from steam into mechanical work, which then drives generators or machinery. While the blades, rotors, and casing often get the most attention, a key internal component—the steam turbine diaphragm—plays a pivotal role in guiding steam, controlling pressure, and ensuring optimal turbine efficiency.

Understanding the function of a diaphragm in a steam turbine, its design principles, and why maintaining its integrity is essential is crucial for engineers, operators, and maintenance planners. This article explores the core role of diaphragms in steam turbines, their impact on performance, and how proper repair and maintenance can extend turbine life.

What Is a Steam Turbine Diaphragm?

A steam turbine diaphragm is a stationary component positioned between successive stages of rotor blades within a steam turbine. Its primary purpose is to direct and control the flow of high-pressure steam as it passes through each stage. Unlike rotor blades, diaphragms do not rotate; instead, they provide structural and aerodynamic guidance to optimize energy transfer.

Diaphragms typically consist of:

- Fixed blades or nozzles: These are carefully shaped to accelerate and guide steam onto the next row of rotor blades.

- Casing support: The diaphragm is securely mounted within the turbine casing to ensure precise alignment.

- Sealing elements: These prevent steam leakage around the blades, maintaining pressure differentials essential for turbine performance.

By controlling steam velocity and direction, steam turbine diaphragms enable smooth energy conversion from thermal to mechanical power while reducing turbulence and stress on rotor blades.

For detailed repair or refurbishment solutions, you can explore services for steam turbine diaphragms provided by Allied Power Group.

The Function of a Diaphragm in a Steam Turbine

The primary function of a diaphragm in a steam turbine is to control and guide the steam efficiently from one stage of the turbine to the next. This involves several specific roles:

1. Directing Steam Flow

Steam entering a turbine has high pressure and velocity. Diaphragms channel this energy toward rotor blades at the correct angle, maximizing the kinetic energy that can be converted into rotational motion. Proper alignment and aerodynamic shaping reduce:

- Flow separation

- Vortex formation

- Turbulence

These improvements result in smoother operation and enhanced mechanical efficiency.

2. Controlling Pressure and Velocity

Diaphragms act as a throttle for steam, converting some pressure energy into kinetic energy. This function ensures:

- The steam impinges on rotor blades at the optimum speed

- Consistent stage pressure differentials

- Prevention of overloading on downstream stages

By maintaining controlled velocity and pressure, diaphragms protect rotors from excessive wear and improve overall turbine efficiency.

3. Maintaining Steam Path Integrity

In multi-stage turbines, diaphragms also function as a structural separator between stages, maintaining steam path integrity. They:

- Prevent steam from bypassing the rotor (leakage)

- Reduce internal recirculation

- Minimize erosion and vibration in downstream blades

Through these roles, diaphragms contribute directly to the longevity of the turbine and consistent power output.

Design Considerations for Steam Turbine Diaphragms

The design of a diaphragm is complex and highly specialized, tailored to each turbine’s operational requirements. Key design factors include:

1. Aerodynamic Blade Profiles

Diaphragm blades are precisely shaped to:

- Accelerate steam

- Control flow angles

- Minimize pressure losses

Advanced Computational Fluid Dynamics (CFD) simulations are often used to optimize blade geometry for maximum efficiency.

2. Thermal and Mechanical Stress Management

Diaphragms operate under extreme temperatures, often exceeding 500°C, and high-pressure steam. Materials are carefully selected to resist:

- Thermal expansion

- Creep

- Fatigue

High-grade alloys and coatings ensure the diaphragms withstand long-term thermal cycling without deformation.

3. Sealing and Clearance

Proper clearance between diaphragm and rotor blades is critical. Too tight, and thermal expansion may cause rubbing; too loose, and steam leakage reduces efficiency. Modern designs incorporate labyrinth seals, brush seals, or advanced metallic coatings to manage these tolerances.

4. Modular Design for Maintenance

Many turbines use modular diaphragms that allow individual stages to be removed, repaired, or replaced without dismantling the entire rotor. This modularity facilitates faster turnaround and reduced downtime.

See also: Reel in the Perfect Trip: Essential Factors for Choosing Fishing Charters

The Impact of Diaphragms on Turbine Efficiency

Steam turbine efficiency depends heavily on the effectiveness of diaphragms. Their contribution can be summarized as follows:

1. Maximizing Energy Conversion

By directing steam optimally onto rotor blades, diaphragms ensure more of the thermal energy is converted into mechanical rotation, boosting the turbine’s output.

2. Reducing Mechanical Stress and Wear

Proper steam guidance reduces vibration and uneven loading on rotors, minimizing blade erosion, fatigue, and mechanical failures.

3. Enhancing Stage-to-Stage Performance

Diaphragms regulate the pressure drop across each stage. Controlled energy extraction ensures consistent stage performance, leading to smoother turbine operation and extended life of capital components.

4. Preventing Efficiency Loss Due to Leakage

Sealing and precise blade alignment minimize bypass leakage, which can reduce overall efficiency by 2–5% if left uncorrected. Even minor improvements in steam path efficiency have a significant impact over large-scale power operations.

Maintaining Diaphragm Integrity: Why It Matters

The integrity of steam turbine diaphragms is crucial for safe and efficient turbine operation. Common issues include:

- Blade erosion from wet steam

- Corrosion due to chemical contaminants

- Cracks from thermal fatigue

- Misalignment from mechanical vibration

Failure to maintain diaphragms can lead to:

- Unexpected turbine shutdowns

- Reduced output and efficiency

- Increased maintenance costs

- Shortened rotor and casing lifespan

Regular inspection, repair, and refurbishment help prevent these problems. Experienced providers offer component repair services that restore diaphragms to near-original condition, ensuring safe and reliable operation.

You can contact Allied Power Group for expert guidance and repair solutions for your steam turbine diaphragms.

Repair and Refurbishment of Steam Turbine Diaphragms

Modern repair techniques allow operators to restore diaphragms instead of replacing them entirely. Key repair approaches include:

1. Blade and Nozzle Reprofiling

- Restoring aerodynamic surfaces

- Repairing minor wear or erosion

- Recoating protective surfaces

2. Crack Repair and Welding

- Precision welding for fatigue cracks

- Stress relief to prevent future propagation

3. Coating and Surface Protection

- Thermal barrier or erosion-resistant coatings

- Improved corrosion resistance

4. Alignment and Fit Verification

- Ensuring precise clearances with rotors

- Labyrinth seal inspections

- Verification using NDT methods

These repairs extend diaphragm life, reduce downtime, and improve turbine efficiency while controlling maintenance costs.

Choosing the Right Partner for Diaphragm Repair

Working with an experienced service provider ensures that repairs meet OEM standards and industry best practices. Allied Power Group offers:

- Advanced inspection and repair techniques

- Proven refurbishment methods for multi-stage turbines

- Rapid turnaround to minimize downtime

- Full documentation and quality assurance

Conclusion

Steam turbine diaphragms may be stationary components, but their role in guiding steam, controlling pressure, and maintaining efficiency is fundamental to turbine performance. Understanding the function of a diaphragm in a steam turbine highlights why precise design, maintenance, and timely repair are essential.

By maintaining diaphragm integrity through inspection, repair, and refurbishment, operators can achieve:

- Improved turbine efficiency

- Reduced mechanical stress and wear

- Extended service intervals and turbine life

- Lower operational costs

Investing in high-quality diaphragm maintenance with a trusted partner like Allied Power Group ensures turbines operate reliably and efficiently for years to come. For expert guidance or service inquiries, visit the Contact Us page.